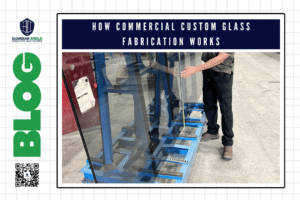

Commercial glass plays a critical role in how Florida businesses look, function, and protect their spaces. From storefronts and interior partitions to safety barriers and architectural features, custom glass is used across many commercial environments. Yet for many business owners and project managers, how commercial glass fabrication actually works and how Florida standards influence it, remains unclear.

This guide is designed to explain commercial custom glass fabrication from an educational standpoint, focusing on material choices, performance implications, and Florida-specific standards. Rather than detailing fabrication steps or promoting services, this article helps commercial clients understand what matters most when evaluating custom glass for business environments.

What “Commercial Custom Glass Fabrication” Really Means

In commercial settings, glass is rarely a one-size-fits-all product. Custom fabrication refers to glass that is manufactured to meet specific size, performance, and safety requirements based on how and where it will be used.

From an educational perspective, fabrication involves aligning three core factors:

- Intended use (storefront, interior, safety barrier, etc.)

- Performance requirements (strength, impact resistance, durability)

- Regulatory compliance (Florida building codes and safety standards)

Understanding these factors helps business owners ask the right questions before any glass is selected or installed.

Why Florida Standards Shape Commercial Glass Decisions

Florida has some of the most stringent building codes in the United States, particularly for commercial properties. These regulations exist because commercial spaces often:

- Serve large numbers of occupants

- Face environmental stress from heat, humidity, and storms

- Require predictable safety performance

Florida standards influence not only how glass is installed, but also what type of glass is appropriate for different commercial applications.

Common Glass Materials Used in Commercial Fabrication

Rather than focusing on fabrication steps, it’s more useful for business owners to understand the materials themselves and what they’re designed to do.

Laminated Glass

Laminated glass consists of multiple layers bonded together with a strong interlayer. In commercial environments, it is commonly associated with safety and impact resistance.

Educational considerations:

- Holds together if cracked

- Reduces fall-through risk

- Offers predictable behavior under stress

Laminated glass is often preferred where occupant safety and durability are priorities.

Tempered Glass

Tempered glass is heat-treated to increase strength compared to standard glass. When it breaks, it shatters into small, blunt fragments rather than sharp shards.

Educational considerations:

- Stronger than untreated glass

- Designed to reduce injury risk

- Often used in interior commercial applications

Tempered glass is commonly used where impact resistance is needed but laminated performance is not required.

Insulated Glass Units (IGUs)

Insulated glass units combine multiple panes separated by air or gas-filled spaces. In commercial environments, they are often associated with energy efficiency and thermal performance.

Educational considerations:

- Helps manage interior temperatures

- Reduces heat transfer

- Supports energy-conscious building design

In Florida’s climate, thermal performance is a major consideration for commercial properties.

Understanding “Options” Without Turning It Into a Product List

When commercial clients hear “options,” they often assume it means styles or upgrades. From an informational standpoint, options refer to functional choices that affect performance, safety, and compliance.

Examples of decision-level options include:

- Glass thickness based on application

- Safety behavior if glass is damaged

- Environmental exposure considerations

These choices influence how glass performs over time, especially in Florida’s demanding climate.

How Florida Building Codes Influence Glass Performance

Florida Building Code requirements apply differently depending on where glass is used in a commercial space. Factors such as height, occupancy, and exposure all play a role.

From a high-level educational perspective, codes address:

- Impact and load resistance

- Safety in elevated or public-access areas

- Predictable failure behavior

Understanding that codes shape performance expectations, not just installation rules helps commercial clients make informed planning decisions.

Commercial Safety Considerations Beyond Appearance

In commercial settings, safety is not optional. Glass must perform reliably in environments with frequent use, public access, and potential impact.

Safety-focused considerations include:

- How glass behaves if damaged

- Whether barriers remain intact

- How occupants are protected

These considerations explain why certain glass materials are preferred in commercial fabrication, especially in Florida.

Environmental Factors Unique to Florida

Florida’s environment places additional demands on commercial glass. Heat, humidity, UV exposure, and coastal conditions all affect material performance.

From an educational standpoint, commercial glass must:

- Resist moisture-related degradation

- Maintain clarity and strength over time

- Perform consistently in fluctuating temperatures

These factors often influence material selection long before fabrication begins.

Visual Performance and Commercial Design Intent

Beyond safety and compliance, glass also plays a visual role in commercial design. Businesses often use glass to:

- Create transparency

- Support brand image

- Enhance customer experience

Understanding how glass contributes to visual openness helps commercial clients align design goals with material performance.

Best Practices for Commercial Clients Evaluating Custom Glass

Rather than focusing on fabrication steps, commercial clients benefit more from understanding best-practice thinking.

Educational best practices include:

- Clarifying how the glass will be used

- Understanding applicable Florida standards

- Prioritizing safety and durability alongside design

This approach reduces risk and supports long-term performance.

Guardian Shield Windows & Doors Supporting Informed Commercial Decisions

At Guardian Shield Windows & Doors, we help Florida commercial clients understand how custom glass fabrication aligns with safety standards, performance expectations, and regulatory requirements. Our role begins with education ensuring business owners and project teams have clarity before decisions are made.

By focusing on materials, standards, and best practices, we support smarter commercial planning without overwhelming clients with technical process details.

Informed Understanding Leads to Better Outcomes

Commercial custom glass fabrication is not just about manufacturing it’s about aligning material behavior, safety expectations, and Florida standards with real-world use.

By understanding how materials differ, why Florida regulations matter, and what performance considerations apply, commercial clients can approach custom glass decisions with confidence.

When glass is chosen with knowledge and context, it becomes a reliable, long-term asset for Florida commercial spaces.

Get Informed Guidance on Commercial Custom Glass in Florida

Understanding commercial custom glass fabrication involves more than knowing materials or terminology. Florida building standards, safety expectations, and long-term performance all influence how glass should be evaluated for commercial use.

Guardian Shield Windows & Doors works with Florida business owners, architects, and property managers to help them understand how different glass materials, performance considerations, and regulatory requirements apply to real-world commercial environments. Our focus is on education first so decision-makers can plan confidently before moving forward with any fabrication or design choice.

If you’re evaluating custom glass for a commercial project and want clarity on materials, options, or Florida standards, a consultation can help you better understand what matters most for your specific application.Request an informational consultion with us to discuss commercial custom glass considerations for your Florida project.\