When business owners think about custom commercial glass, they often picture the sleek storefronts, impressive office partitions, or glass railings that elevate a building’s appearance. But behind every panel of glass lies a careful, detailed commercial glass fabrication process, a journey that transforms raw materials into durable, functional, and stylish architectural elements.

At Guardian Shield Windows and Doors, we believe understanding this process helps our clients make informed decisions for their projects. Here’s a closer look at what happens from the very first blueprint to the final installed panel.

1. The Blueprint and Design Consultation

Every project starts with a conversation. Our team collaborates with architects, builders, and business owners to understand the project’s goals, structural requirements, and design vision. At this stage, we create detailed blueprints and digital renderings that ensure every measurement, curve, and angle is precise.

The design phase is crucial because glass must balance aesthetics with safety, durability, and compliance with Florida’s commercial building codes.

2. Selecting the Right Glass Materials

Not all glass is created equal. Depending on the project, our team recommends specialized materials such as:

- Tempered glass for strength and safety.

- Laminated glass for impact resistance and soundproofing.

- Insulated glass units (IGUs) for energy efficiency in large commercial spaces.

Each type is chosen based on how the glass will function whether it’s for a storefront, office wall, railing, or custom architectural feature.

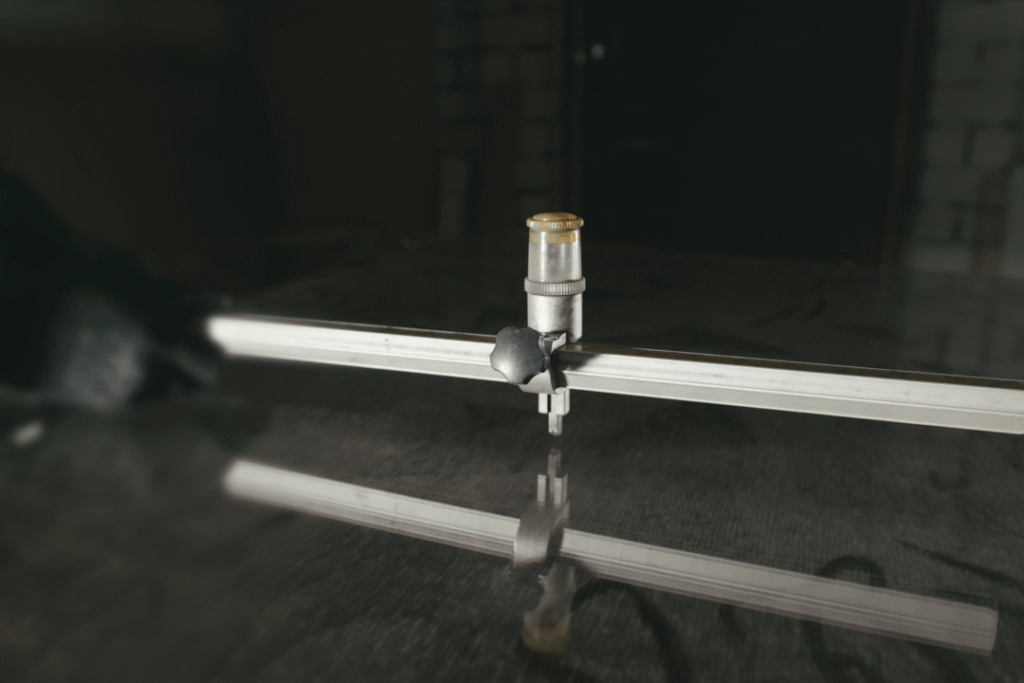

3. Precision Cutting and Shaping

Once materials are selected, the raw glass sheets move into fabrication. Using advanced machinery, panels are cut with laser-guided accuracy to match exact blueprint specifications. For projects requiring curves, bevels, or unique shapes, CNC machines and diamond-tipped tools ensure flawless execution.

This stage transforms a plain glass sheet into a customized component ready for strengthening and finishing.

4. Strengthening and Safety Treatments

Glass intended for commercial use must withstand heavy daily wear and potential impacts. Through heat-treating and lamination processes, panels gain additional durability. For hurricane-prone areas like Florida, impact-resistant treatments are often applied to meet or exceed building code requirements.

This step guarantees that the final panels aren’t just beautiful, they’re built to last.

5. Surface Finishing and Detailing

Aesthetic touches are applied here. Options like tinting, frosting, sandblasting, or custom etching allow businesses to personalize their glass while also improving functionality. For example, tinted finishes reduce glare and heat, while etched designs add branding or privacy to interior partitions.

6. Quality Control and Inspection

Before any panel leaves the fabrication facility, it undergoes strict quality control checks. Our technicians inspect each piece for accuracy, strength, and finish quality to ensure it meets the highest standards of safety and performance.

7. Professional Installation and Final Fit

The last stage of the commercial glass fabrication process is installation. Precision doesn’t stop at the shop it carries through to the job site. Our installers carefully secure panels into place, ensuring a seamless fit that enhances both the structural integrity and visual appeal of the building.

Why Businesses Choose Guardian Shield Windows and Doors

Commercial projects demand more than just glass; they require expertise, precision, and a commitment to safety. At Guardian Shield Windows and Doors, we bring decades of experience to every project, combining high-tech fabrication methods with a customer-first approach. From the first blueprint to the final installed panel, we make sure your investment delivers long-lasting beauty, performance, and value.

Ready to bring your vision to life? Contact Guardian Shield Windows and Doors today to schedule your consultation and learn how our custom glass solutions can transform your commercial property.